Benefits of using a surface water flow control system

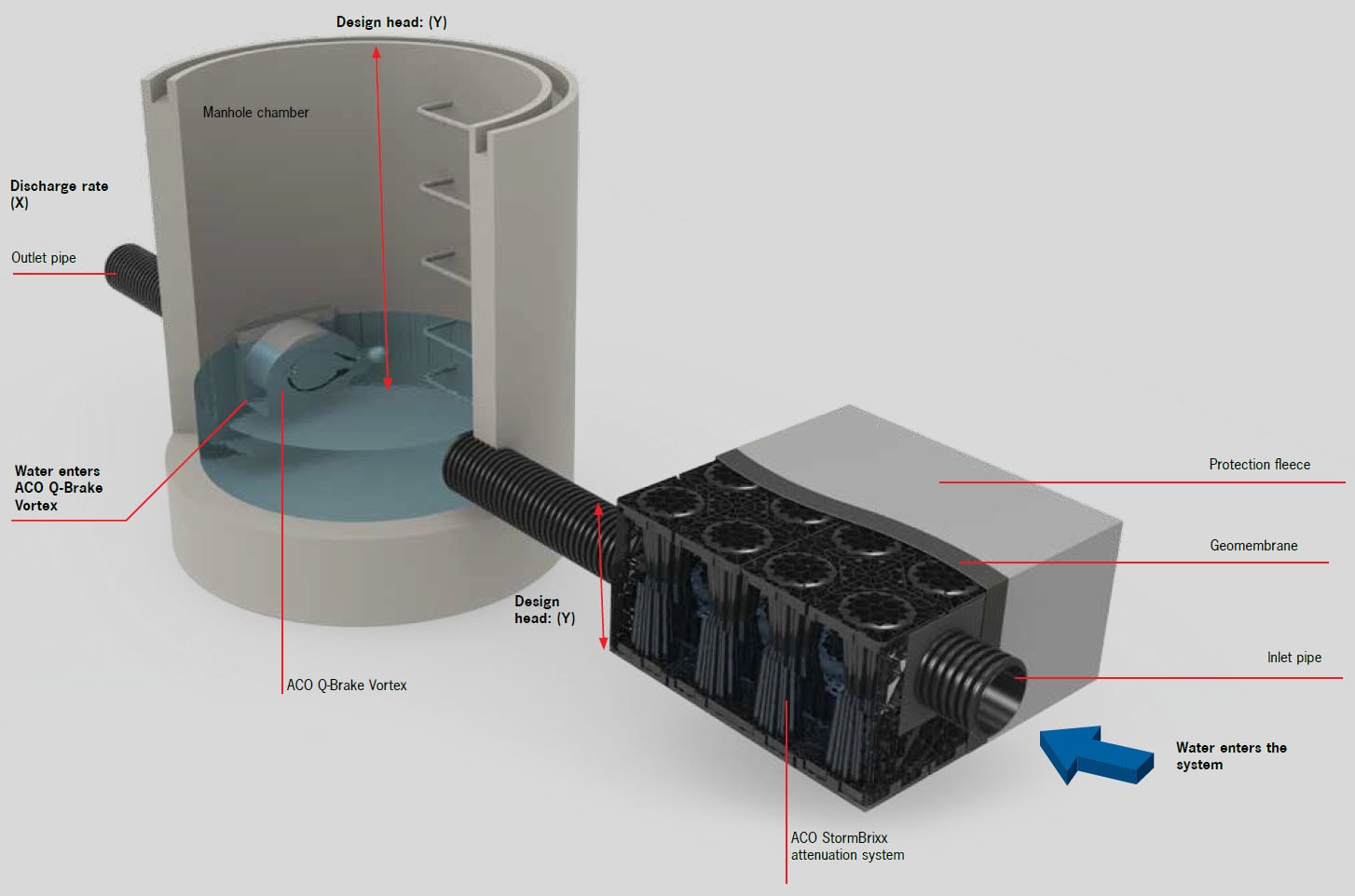

Storage and the controlled release of clean water into the natural environment is an important aspect of managing surface water in the LID approach. Municipal sewer regulations now gives overall responsibility to the local regulatory body to impose, where appropriate, the discharge rate of a surface water fl ow control system. ACO’s range of fl ow control systems can be used in conjunction with ACO’s award-winning attenuation and infiltration system, ACO StormBrixx, to provide a fully integrated storm water control system meeting the requirements of the regulations.

This diagram simulates how the ACO StormBrixx system is used to provide storm water attenuation, whilst the ACO Q-Brake is used to regulate the rate of discharge from the development into the watercourse or sewer network.

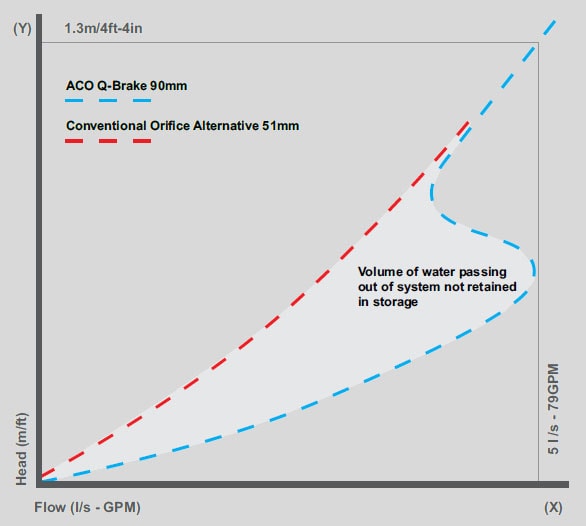

This benefit is best demonstrated in the example opposite. The conclusion of the example means that upstream storage can be reduced by 32m3 (1,130ft3 ) compared to using a traditional flow control system.

Example:

There is a development project in Whitby, Ontario, with a catchment area of 96,875ft2 (0,000m2). The project has predefined design criteria of a 1 in 25 year storm, with a 10% increase in rainfall intensity over the lifetime of a development, due to climate change, and runoff from the site must not exceed 79GPM (5 I/s) at a design head of 4ft-4in (1.3m).

Results:

Using drainage software, ACO has identified the potential saving in upstream storage requirements when using a Q-Brake instead of a traditional orifice plate. Results are summarized below:

- An ACO Q-Brake system would require a 3.75” (95mm) dia orifice to best manage the design head and flow, which lead to 10,630ft3 (301m3) upsteam storage being required.

- An equivalent orifice plate system would require a 1.75” (44mm) dia orifice and lead to 11,760ft3 (333m3) upstream storage being required to deliver against the same design criteria.

- ACO Q-Brake would therefore reduce upstream attenuation requirements by approximately 1,130ft3 (32m3) – (10%) relative to a tradional orifice plate system.

The increased orifice diameter also means the Q-Brake orifice has a cross sectional area >4.6 that of the equivalent traditional orifice plate. Therefore, it is less prone to blockage than a traditional orifice plate flow controller.

Discharge characteristics